Ultrasound’s About Right – Waveco® The Brilliant New Tech in Protein and Maturation

We bet you never thought that a water bath could do more than cook at low temperatures. New science developed over the last few years has shown that by using ultrasound, a water bath can be turned into a maturation machine that drastically cuts the time meat, fish and vegetables ripen or mature.

Ultrasound works in food preparation in a unique way. By treating liquid with ultrasound at specific frequencies tiny bubbles are created every second and when they shrink and form again pressure is exerted in the liquid. Lost? Yes, us too. This is bonkers science but stick with it.

Imagine this: You put a piece of fresh, non-matured meat into a vac-pac bag and put it into a water bath. You press a few buttons and the machine goes to work. The result, sometime later, is mature meat that has no weight loss or shrinkage and softness that only comes with ageing. It works with meat, fish and vegetables.

What does this mean? Take pheasant, for example. This is often fresh and hard to cook because chefs and customers don’t like the old tastes of hung game – the traditional way to soften up game. By using ultrasound, the pheasant breast can be matured at room temperature in the water bath using Ultrasound into something completely new. The result is softer and has the maturation required to be easier to cook with better flavour.

What does this mean? Take pheasant, for example. This is often fresh and hard to cook because chefs and customers don’t like the old tastes of hung game – the traditional way to soften up game. By using ultrasound, the pheasant breast can be matured at room temperature in the water bath using Ultrasound into something completely new. The result is softer and has the maturation required to be easier to cook with better flavour.

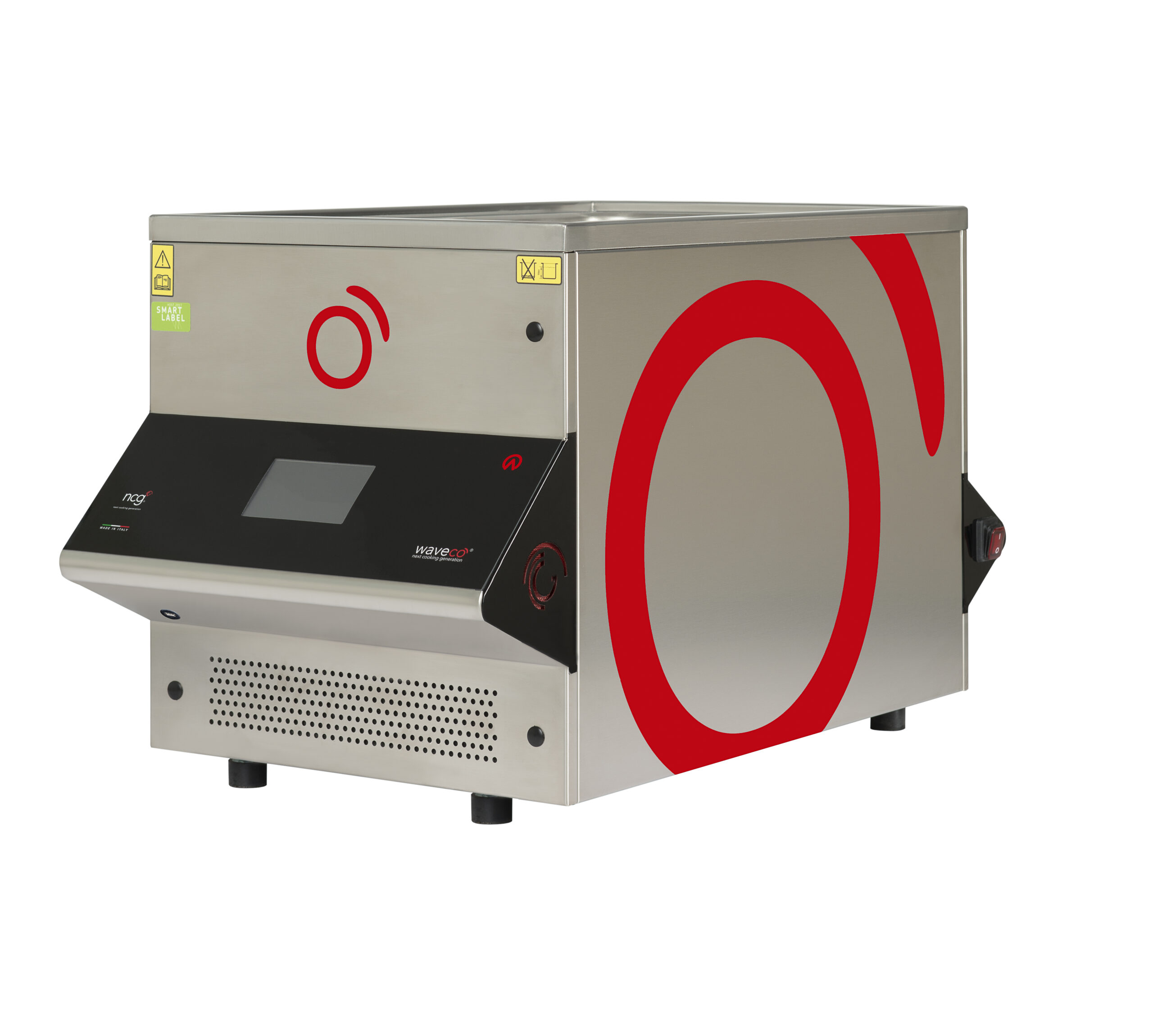

Interested? We were. This science is not widely available yet, but those chefs interested in the technology should look at the new machines by Waveco®. This Italian company has patented technology that will revolutionise the way you treat meat, fish and vegetables and enable you to use younger meat – which hasn’t shrunk due to traditional mentors – and guarantee specific maturation.

Waveco® standardises the meat manipulation process by ensuring quicker meat ageing while reducing weight loss without any loss in terms of nutritional values. The process is performed at room temperature and ensures softer, juicier meat.

The Waveco® method allows you to improve the procedures you usually perform in your kitchen while shortening preparation time, reducing cooking temperature and improving the subsequent phase of food storage, thanks to the action of ultrasounds, which reduces the bacterial load and therefore considerably extends the shelf life of the final product.

Waveco® will make its Chefs’ Forum debut at a special event all about meat at Omnino Steakhouse in London’s City District later this month, any chefs wishing to know more or to book a demonstration at their restaurant should contact Evandro Bottecchia, Head of Sales at DCI Maintenance: evandro@dcimaintenance.co.uk