The Beyond Oil Method Chefs Are Using to Make Oil Last Longer

Every chef recognises the moment when the fryer begins to turn against you. The oil appears darker. The aroma shifts. Chips start colouring too quickly, breaded items lose their crispness, and the kitchen fills with that heavy, burnt frying smell that lingers on your whites long after service.

Every chef recognises the moment when the fryer begins to turn against you. The oil appears darker. The aroma shifts. Chips start colouring too quickly, breaded items lose their crispness, and the kitchen fills with that heavy, burnt frying smell that lingers on your whites long after service.

And yet, most kitchens carry on. Not because anyone wants to serve food with tired oil, but because oil is expensive, deliveries aren’t getting cheaper, and replacing it each time it begins to run out can feel like pouring profit straight down the drain.

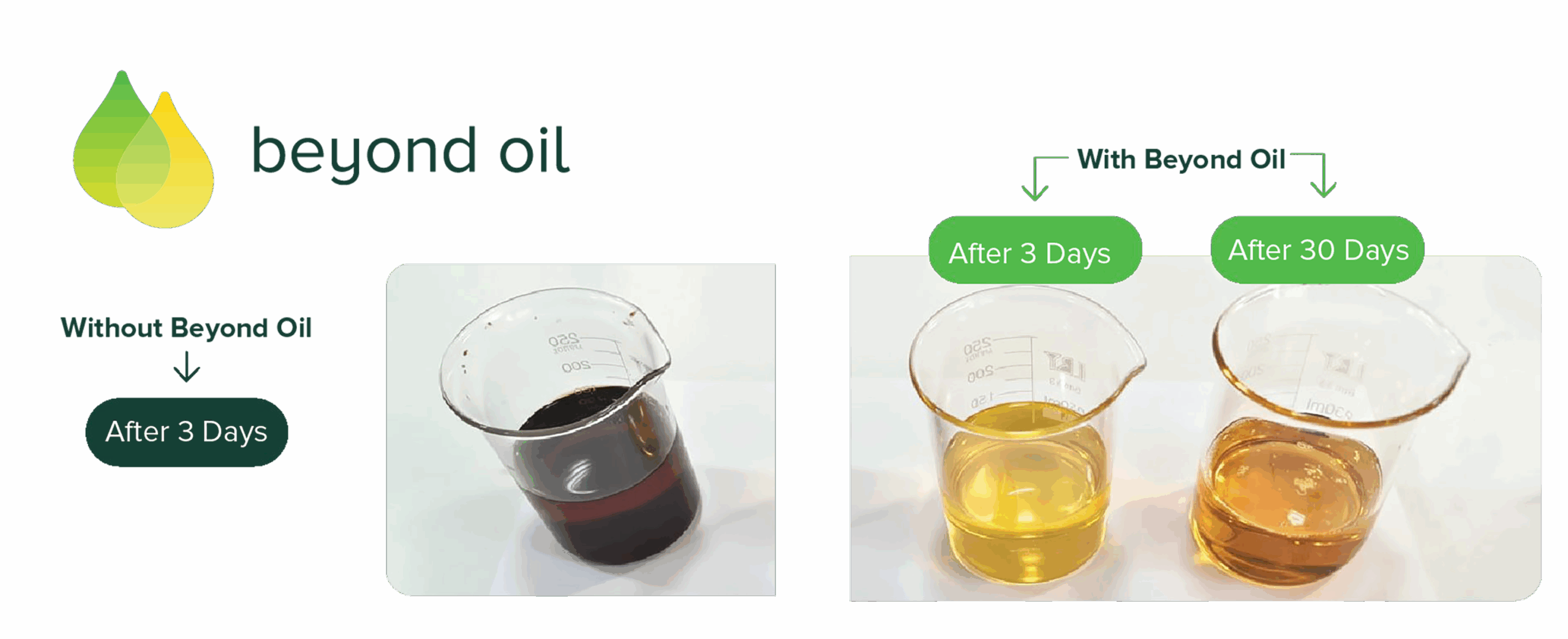

The harsh truth is that in many commercial kitchens, frying oil begins to degrade within 3 to 5 days. In reality, it is often used well beyond that point just to keep the business operational.

That’s where Beyond Oil is starting to garner serious attention. It isn’t a new fryer, a complicated kitchen gadget, or another product that makes lofty promises but adds extra steps to your day. Beyond Oil is a longevity powder designed to function within your existing filtration protocol. The aim is simple: keep frying oil stable, cleaner, and consistent for longer by removing the impurities that cause it to break down.

That’s where Beyond Oil is starting to garner serious attention. It isn’t a new fryer, a complicated kitchen gadget, or another product that makes lofty promises but adds extra steps to your day. Beyond Oil is a longevity powder designed to function within your existing filtration protocol. The aim is simple: keep frying oil stable, cleaner, and consistent for longer by removing the impurities that cause it to break down.

What makes this interesting for chefs is that it addresses more than just surface mess. When oil starts breaking down, it’s not only crumbs and bits that become problematic. Old oil produces smoke, harsh flavours, and fumes that make the kitchen unpleasant for the team. It can also cause the build-up of unwanted trans fats on the plate, and it increases hidden operational costs through extra cleaning, heavier chemical use, more labour, and sometimes even downtime.

Beyond Oil’s greatest benefit is extending the life of oil from three days to 30 days – that is ten times longer. This revolutionary product can help reduce oil purchases by up to 50%, resulting in fewer change-outs and less waste. For operators monitoring every margin, that’s a significant win, especially when the return on investment is seen as paying for itself through oil savings alone.

Beyond Oil’s greatest benefit is extending the life of oil from three days to 30 days – that is ten times longer. This revolutionary product can help reduce oil purchases by up to 50%, resulting in fewer change-outs and less waste. For operators monitoring every margin, that’s a significant win, especially when the return on investment is seen as paying for itself through oil savings alone.

But chefs won’t stick with anything just because it saves money. It has to perform on the pass. Cleaner, fresher oil directly affects food quality, and Beyond Oil is designed to support consistently golden, crisp fried food with better taste, texture, and colour – whether customers are eating it in-house or it’s travelling out the door for delivery.

But chefs won’t stick with anything just because it saves money. It has to perform on the pass. Cleaner, fresher oil directly affects food quality, and Beyond Oil is designed to support consistently golden, crisp fried food with better taste, texture, and colour – whether customers are eating it in-house or it’s travelling out the door for delivery.

There’s also an increasing discussion about what “better frying” means for customers. Beyond Oil is created to physically eliminate harmful toxins, trans fats, and other unwanted compounds that can develop during frying, which is presented as an improvement over basic filtration method.

And at a time when sustainability is becoming a genuine commercial metric, reducing oil consumption also means decreasing waste, lowering scope three emissions. This supports ESG commitments and helps diminish the broader impact on the supply chain, which more businesses are now expected to monitor.

By prolonging the life of oil, we decrease the demand for oil, which leads to less deforestation, fertiliser use, refining, shipping, and handling. This prevents the emission of 3.81 kg of CO2e for each litre of oil that is not utilised.

For chefs, however, the most immediate benefit might be the simplest: a calmer fryer section. Less splatter, fewer burning smells, reduced odours, and cleaner vents and hoods can make the kitchen safer. Additionally, not inhaling the hazardous, toxic, carcinogenic fumes that harm the kitchen staff working on the fryer daily makes it more pleasant to work in – and that matters when you’re trying to retain good staff in your team.

In short, Beyond Oil isn’t aiming to reinvent frying. It’s about making it cleaner, more affordable, and more reliable, without forcing chefs to compromise on quality.

For more information on how Beyond Oil can transform your frying system, contact:

For more information on how Beyond Oil can transform your frying system, contact:

Adrian Sagman for a no-obligation chat on: 07830 752875 or email: adrians@beyondoil.co